Key Takeaways

- Researchers developed a copper-based alloy that maintains shape memory properties even at -200°C.

- This alloy can significantly improve equipment reliability for space missions in extreme cold.

- The new material offers flexibility in applications, allowing for efficient thermal control systems.

Innovative Alloy for Extreme Cold

A team of scientists has created a groundbreaking copper-aluminum-manganese alloy that retains its shape memory properties at extremely low temperatures, down to -200°C. Shape memory alloys, which operate like mechanical memory foam, can be deformed when cold and revert to their original shape upon heating. This unique feature makes them ideal for actuators in various machinery.

Traditional shape memory alloys, commonly made from nickel and titanium, face substantial limitations in extreme temperatures, becoming ineffective below -20°C. Although a few can work at temperatures below -100°C, their practical applications remain limited, posing challenges for space technology where temperatures often drop well below -100°C.

Researchers from Tohoku University and the Japan Aerospace Exploration Agency (JAXA) have successfully tested their new alloy at -170°C, demonstrating its ability to effectively control heat transfer by switching between contact and non-contact states. This major breakthrough could lead to advancements in materials science and significantly enhance the reliability of space equipment, which is often crucial under harsh conditions in space.

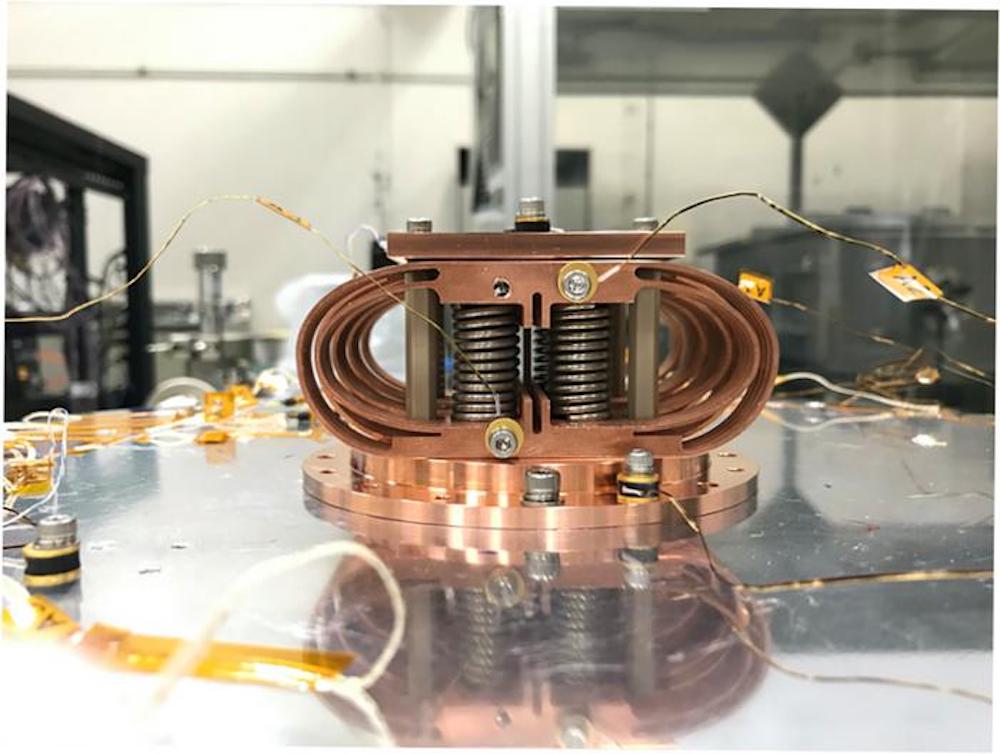

The team also developed a prototype mechanical heat switch using this alloy, capable of automatically regulating heat flow in response to temperature variations. By tweaking the alloy’s composition, its operational temperature can be adjusted, making it adaptable for diverse applications in space missions.

The introduction of this new material promises simplicity and reliability, which are essential for future space endeavors. As humanity aims to explore more challenging environments, such resilient and efficient technologies will be vital for mission success. The ability of this new alloy to function in extreme conditions could make spacecraft lighter, less complex, and far more dependable.

The content above is a summary. For more details, see the source article.