Key Takeaways

- The Large Space Simulator (LSS) now features a digital twin to streamline operator training.

- This virtual model accurately mimics operations, allowing trainees to practice in realistic scenarios.

- The digital twin software enhances both training and testing capabilities, including simulating equipment failures.

The Large Space Simulator Overview

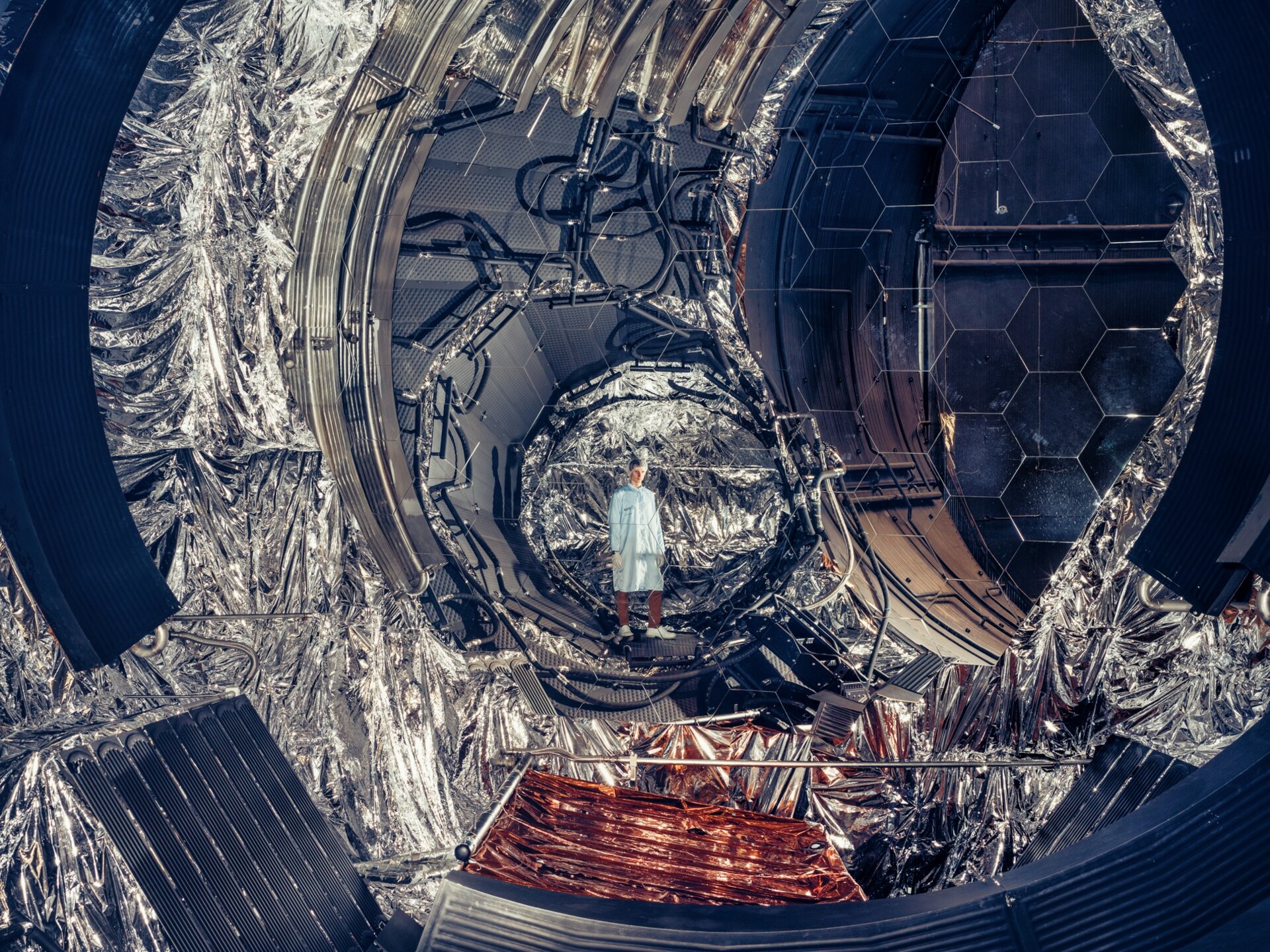

The Large Space Simulator (LSS), situated in the Netherlands, serves as Europe’s largest vacuum chamber and replicates the extreme conditions of space for spacecraft testing. With the capability to create a high vacuum and achieve temperatures as low as -180 °C, the LSS enables engineers to prepare spacecraft for the harsh realities of orbit.

As highlighted by Remko Moeys, an engineer at the European Space Agency (ESA), training new operators has traditionally been a lengthy and complicated process, often taking years to master. A significant barrier has been the limited number of annual test opportunities, which hampers hands-on experience. To address this challenge, the ESA, in collaboration with the Spanish engineering company Empresarios Agrupados, has introduced a digital twin—a highly realistic virtual model of the LSS. This digital twin serves a similar purpose to flight simulators for pilots, offering a comprehensive training experience.

Developed using the ‘EcosimPro’ simulation software, the digital twin allows trainees to interact with a virtual representation of the LSS. The software mirrors the control panels and data displays found in the actual control room, resulting in a seamless blended learning experience. For instance, when a trainee simulates opening a valve, the program generates responses akin to those in real-life operation.

One of the key advantages of the digital twin is its flexibility. Trainees can start, pause, or speed up tests, enabling them to focus on particular scenarios without the need for constant real-time conditions. Additionally, the software can simulate potential failures, such as valve malfunctions or air leaks, providing valuable opportunities for trainees to develop their problem-solving skills in a controlled environment.

Julien Pioton, an LSS operator and test engineer, emphasizes the safety and efficiency of this innovative training tool. By allowing repeated practice of specific test phases, operators can build confidence and enhance their skills without the risks associated with real-life training.

Beyond operator training, the digital twin also plays a vital role in optimizing the LSS. It can be used to conduct virtual assessments of facility changes, rehearse test operations, and simulate abnormal conditions, ensuring that engineers can prepare for any eventuality. Miguel Alcázar, Simulation Manager at Empresarios Agrupados, expressed pride in the rapid completion of this ambitious project, stating that EcosimPro tools have provided significant support not just for the aerospace sector, but also for various other industries.

The LSS has a storied history, with its predecessor constructed 50 years ago. Over the decades, the facility has evolved, accommodating countless spacecraft and their rigorous testing before orbit missions. The integration of the digital twin into the LSS marks a significant advancement, poised to streamline training processes and improve testing efficiency, ultimately paving the way for future innovations in space exploration.

The content above is a summary. For more details, see the source article.