Key Takeaways

- A research team at SUTD developed a 3D printing method to create biodegradable electrical components using cellulose acetate and graphite.

- The novel technique allows for high-concentration conductive fillers, achieving conductivities suitable for applications like flexible circuitry.

- This approach prioritizes sustainability, using biodegradable materials to reduce the environmental impact of electronic production.

Innovative 3D Printing Method Enhances Sustainability in Electronics

As electronic devices become increasingly integral to everyday life, there is a growing demand for sustainable production methods. A team from the Singapore University of Technology and Design (SUTD), led by Associate Professor Michinao Hashimoto, is addressing this need with a groundbreaking 3D printing technique that creates electrically conductive structures from biodegradable materials.

In their study, titled “Extrusion Printing of Electrically Conductive Polymer Composites via Immersion Precipitation,” published in ACS Applied Engineering Materials, the researchers focused on cellulose acetate. This plant-derived plastic is both biodegradable and an environmentally friendly alternative to synthetic polymers. However, traditional printing methods have struggled to effectively process cellulose acetate due to its heat sensitivity.

To overcome these challenges, the research team employed direct ink writing technology, which allows for the extrusion of polymer inks at room temperature. They developed a custom ink composed of cellulose acetate dissolved in acetone mixed with graphite microparticles to introduce electrical conductivity. Nonetheless, the initial attempts resulted in poor print definition due to the rapid evaporation of acetone when exposed to air.

The breakthrough occurred when the team introduced water as a surrounding medium. By extruding the ink directly into water, they initiated a process known as immersion precipitation. This method enabled acetone to evaporate quickly, solidifying the ink in place and preventing it from spreading too much. As Hashimoto noted, this is the first instance of combining immersion precipitation with 3D printing to produce conductive polymer composites.

The researchers’ immersion-based approach allowed them to successfully incorporate graphite fillers at concentrations up to 60% by weight, significantly higher than the 30–50% limit typically encountered in other methods. These printed composites achieved electrical conductivities exceeding 30 S/m, making them suitable for uses such as flexible circuitry and soft sensors.

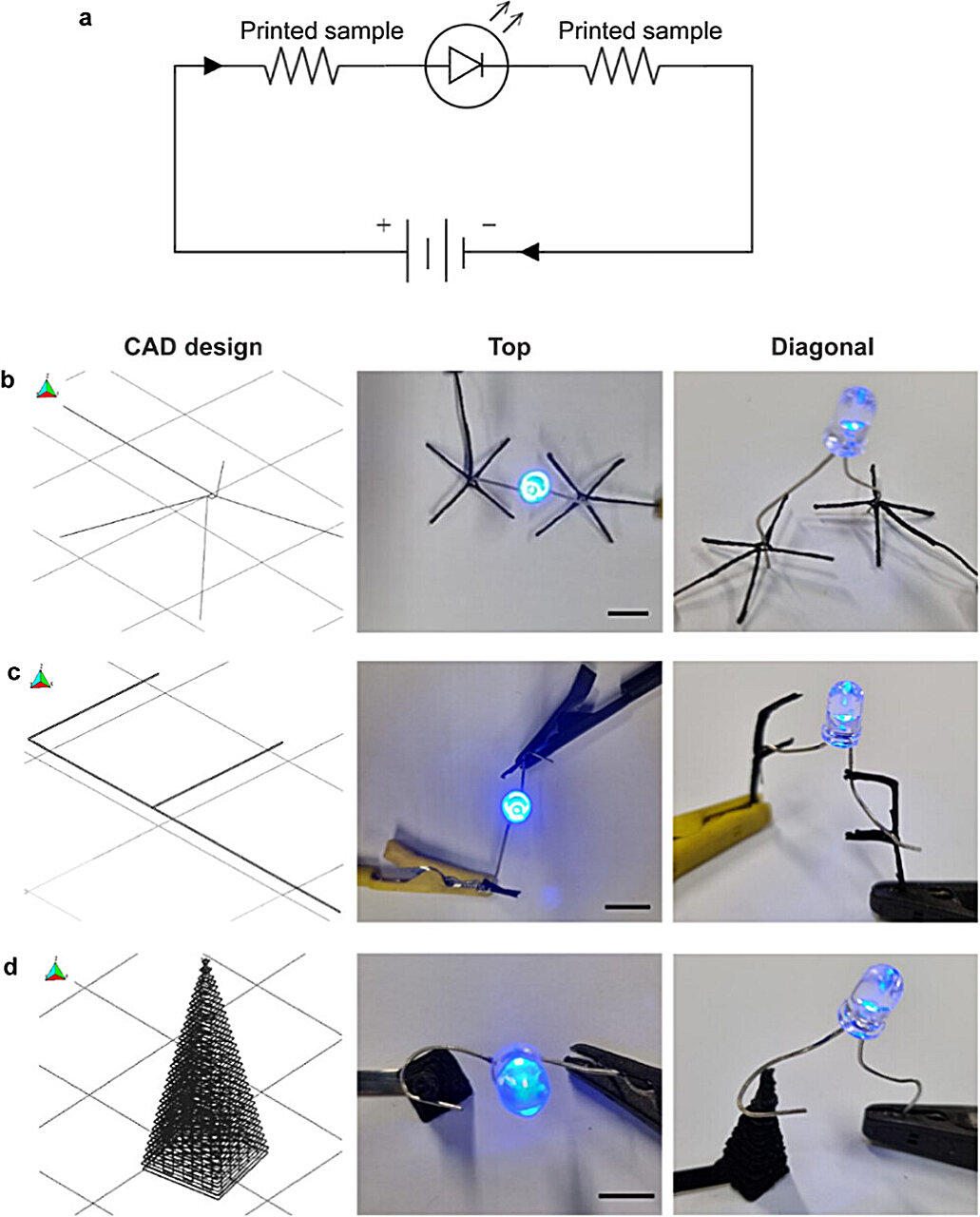

In practical applications, the team demonstrated that their printed materials could complete electrical circuits, successfully powering light-emitting diodes (LEDs). They also showcased the versatility of their technique by printing complex overhanging spiral structures within a gel-based support medium, eliminating the need for traditional scaffolding.

The environmental focus of the project is paramount. Both cellulose acetate and graphite are biodegradable, and acetone is a low-toxicity solvent that degrades easily in the environment. By using these materials, the researchers aim to present a more sustainable pathway for electronic manufacturing.

Future steps include adapting their technique for other polymer-filler combinations and assessing the long-term performance of their printed materials in real-world conditions. The ultimate objective is to create a scalable, cost-effective platform for producing high-performance, sustainable devices. Hashimoto expressed a vision for developing a comprehensive library of printable, functional composites tailored for applications in wearable technology, biosensors, and flexible circuits.

The content above is a summary. For more details, see the source article.