Key Takeaways

- Georgia Tech Research Institute has developed a compact X-Band AESA testbed named XPAT, enhancing air defense systems.

- XPAT features modular design for ease of assembly and maintenance, with advanced thermal management for high-power operations.

- The system’s flexibility allows it to adapt to various applications and future scenarios in radar technology.

Innovative Advancements in AESA Radar Technology

Active electronically-scanned array (AESA) radars are increasingly vital for air and missile defense, as well as in training simulations. Researchers at the Georgia Tech Research Institute (GTRI) have introduced a compact and fully-integrated X-Band polarization-diverse AESA testbed, known as XPAT, aimed at modernizing these systems. This new development is intended for both airborne and ground-based applications, featuring a reconfigurable software-defined RF aperture to fulfill diverse mission requirements.

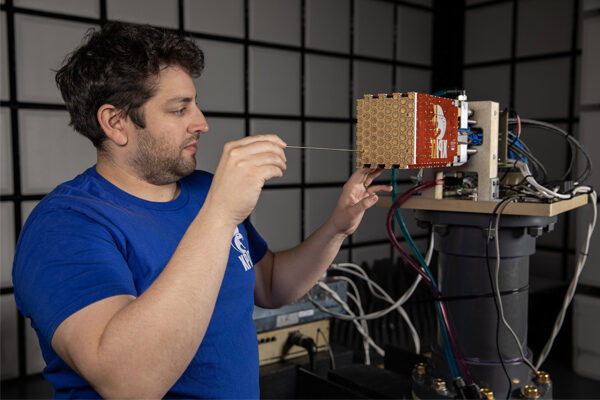

Currently undergoing testing at GTRI’s antenna ranges, XPAT consists of eight-element transmit-receive (T/R) modules, liquid-cooled cold plates designed to minimize thermal gradients, and electromagnetic interference shields for channel isolation. The system’s design allows it to function as a building block adaptable to various planar sizes, facilitating easier assembly and maintenance through blind-mate interfaces for power, control, cooling, and RF connections.

XPAT aims to enhance GTRI’s radar capabilities by providing a high-power, digital phased-array architecture with polarization control. According to Maxwell Tannenbaum, a senior research engineer leading the project, XPAT is designed to replace existing test assets with advanced systems that can better address current and future operational scenarios. The scalable design promotes reliability and minimizes downtime, as it can be field-repaired by replacing subarrays with minimal effort.

Unlike traditional systems, each element in the AESA approach incorporates a transmitter and receiver, allowing the radar to maintain operational functionality even if components fail. As Tannenbaum explained, the system enables continued operation within specifications despite the loss of several elements, which adds to its robustness and reliability.

The innovative cooling system comprises cold plates manufactured through advanced additive techniques, ensuring uniform temperature management of electronic parts. GTRI has filed a patent for this technology, which signifies an important step in the industry’s thermal management strategies. Dante Dimenichi, another senior research engineer at GTRI, emphasized that design challenges included accommodating fluid passages in cold plates as well as components on integrated printed circuit boards (PCBs).

Though specifically developed for X-Band frequencies, GTRI is exploring broader frequency designs to represent various systems with diverse performance needs. The modular nature of XPAT allows for scalability; a large-scale simulator may combine 150 to 200 blocks, while smaller systems could utilize 50 to 60 blocks. Each block is equipped with its own T/R elements, ensuring flexibility in designing radar apertures of varying sizes, depending on power and cooling capabilities.

Supported by GTRI’s Independent Research and Development program, XPAT’s development reflects a collaborative effort from a dedicated team of researchers. The design philosophy prioritizes not just laboratory functionality but also field applicability. Through lessons learned from previous projects and direct feedback from stakeholders, XPAT is positioned to be a significant advancement in radar technology, ready to meet the demands of modern defense scenarios and training simulations.

The content above is a summary. For more details, see the source article.