Key Takeaways

- Stellantis introduces the Intelligent Battery Integrated System (IBIS), consolidating multiple EV components into a single unit.

- IBIS improves energy efficiency by up to 10% and power output by 15%, while reducing weight and charging time.

- The technology aims to be integrated into Stellantis production EVs by the end of the decade.

Innovative Approach to EV Battery Technology

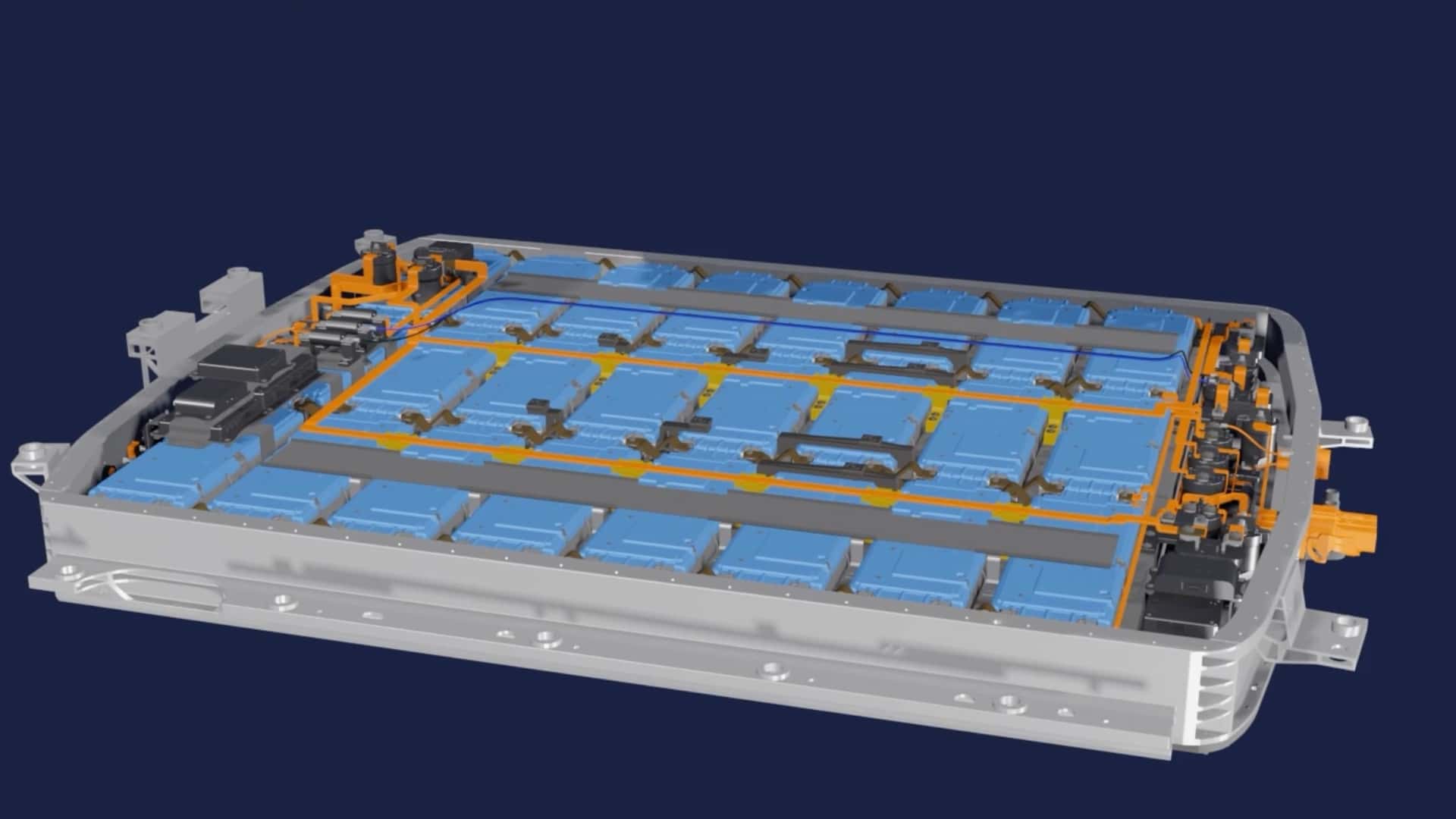

Stellantis has unveiled the Intelligent Battery Integrated System (IBIS), designed to enhance electric vehicle (EV) performance and efficiency by integrating several key components into a single enclosure. Traditionally, EV batteries include a battery pack, inverter, and DC-to-DC converter, leading to inefficiencies. The IBIS aims to streamline this layout, potentially providing more range and higher energy efficiency for everyday electric vehicles.

The first prototype has been tested on the Peugeot E-3008 crossover, which is built on Stellantis’s STLA Medium platform, also used for the Jeep Compass. By embedding the inverter and charger directly into the battery, Stellantis allows for greater flexibility in battery selection. A nickel manganese cobalt (NMC) battery, for instance, can be easily swapped with a lithium iron phosphate (LFP) battery depending on the application—whether for family-oriented cars or commercial vehicles.

Additionally, the IBIS supports both AC and DC electricity, enabling vehicle-to-grid (V2G) functionality. This capability allows vehicles to not only power their electric motors but also feed electricity back to the grid and supply power to the vehicle’s auxiliary systems.

Stellantis claims that its prototype offers significant energy efficiency advancements of up to 10%, along with a power increase of 15% compared to conventional batteries of similar size. For example, an IBIS-equipped battery can deliver 230 horsepower (172 kW), while a traditional battery can provide only 201 horsepower (150 kW). Moreover, the design reduces overall vehicle weight by approximately 88 pounds (40 kg) and frees up to 0.6 cubic feet (17 liters) of additional space for other uses in the vehicle.

Charging times have also seen improvements; a full charge on a 7 kW AC charger takes around six hours using an IBIS battery, compared to seven hours for a standard battery.

The next steps in this development program involve real-world testing to validate the packaging and performance of the IBIS. If successful, Stellantis plans to begin integrating this innovative system into its production electric vehicles by the end of the decade, potentially setting a new standard for efficiency and performance in the EV sector.

The content above is a summary. For more details, see the source article.