Key Takeaways

- Duke University engineers have developed a technique for printing fully recyclable electronics at sub-micrometer scales.

- The innovation could significantly reduce the environmental impact of the $150 billion electronic display industry.

- Carbon-based transistors printed with high precision may enhance U.S. manufacturing in competitive markets.

Innovative Printing Method for Electronics

Researchers at Duke University have successfully designed a method to print highly functional and recyclable electronics utilizing sub-micrometer technology. This advancement stands to transform the electronic display sector, valued at over $150 billion, addressing its pressing environmental concerns as most current manufacturing is performed overseas.

The study, published in the journal Nature Electronics, highlights the critical need for innovative technology to boost U.S.-based manufacturing, which has been increasingly overshadowed by global competitors. Aaron Franklin, a distinguished professor at Duke, emphasized that these carbon-based transistors provide comparable performance to existing industry products and are fully recyclable—an encouraging sign for sustainable technology.

Electronic displays are integral across numerous industries—from televisions and computer screens to automotive displays—yet the majority are produced in countries such as South Korea, China, and Taiwan. Conventional manufacturing methods necessitate high levels of energy and emit considerable greenhouse gases, with an alarming statistic: less than 25% of electronics are recycled.

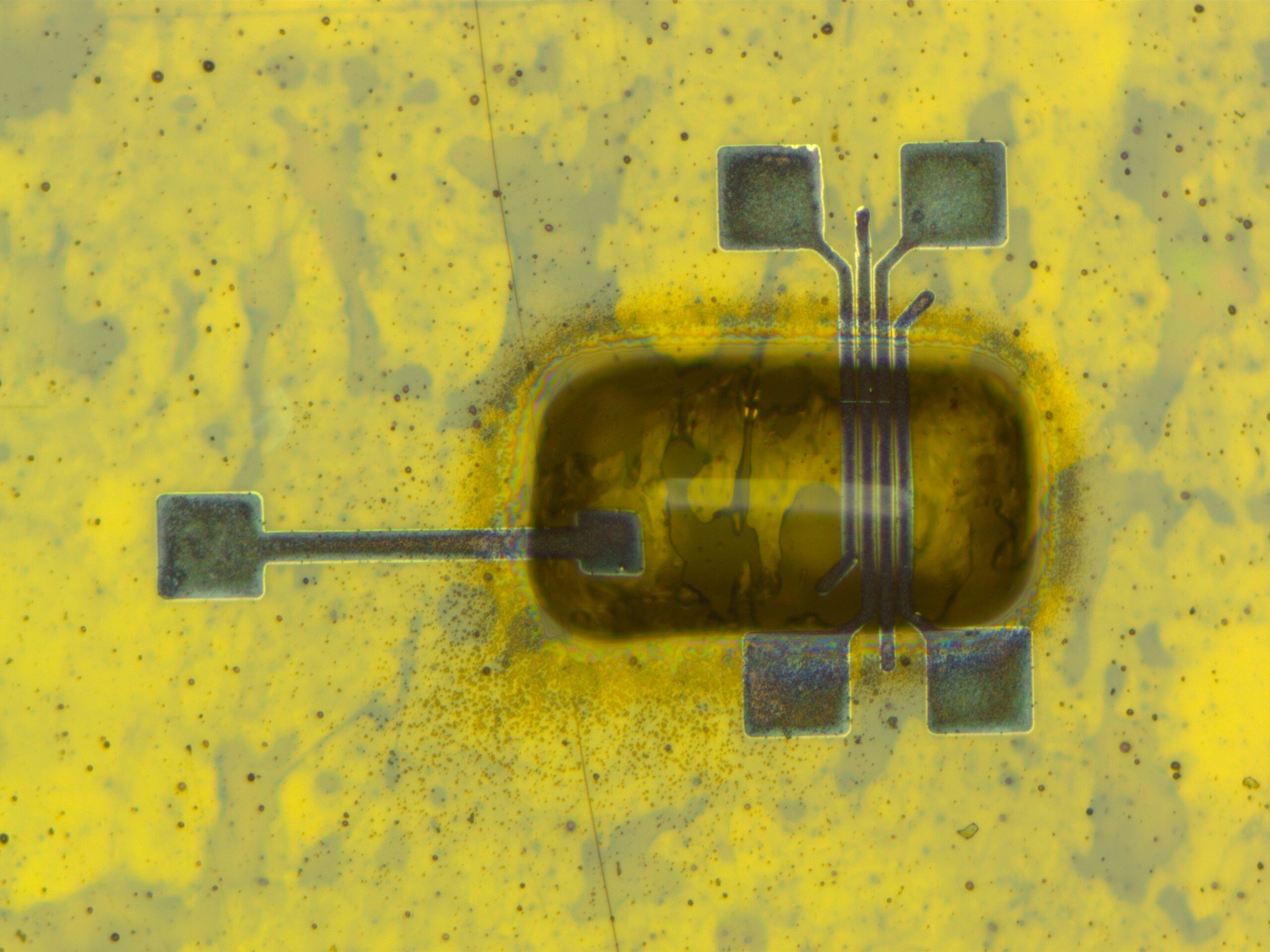

Previously, Franklin’s lab introduced the world’s first entirely recyclable printed electronics, but that effort was limited to aerosol jet printing, incapable of producing features smaller than 10 micrometers. In the latest research, Franklin’s team partnered with Hummink Technologies to surmount these limitations. Their new “high precision capillary printing” technology utilizes natural surface energies to draw minute amounts of ink from tiny pipettes, achieving precise control at the sub-micrometer level.

The collaboration enabled the printing of features tens of micrometers long with gaps that are smaller than one micrometer—essential for the performance of carbon-based thin-film transistors (TFTs) used in display technology. While these techniques will not replace high-performance silicon-based chips, they possess the potential to revolutionize certain markets where low-cost, environmentally friendly solutions are needed.

Franklin noted the significant role of thin-film transistors in digital displays, where they are responsible for controlling each pixel. Prior demonstrations indicated that these printed transistors could power a few pixels of an LCD screen. The current advancement potentially positions them for similar applications in OLED technology, which requires more advanced transistor performance.

Aside from displays, there are promising applications for this technology in enhancing sensor accuracy within chips. However, Franklin believes digital displays present the most immediate opportunity for large-scale adoption, primarily due to the energy efficiency and reduced emissions of the printing process compared to traditional methods.

Despite these promising developments, Franklin expressed concern over the lack of funding for continued research, especially after cuts to a National Science Foundation program intended to support such innovations. The aim moving forward is to secure new avenues of investment to help realize the full potential of this groundbreaking work.

For more information, the full research is documented in the study “Capillary flow printing of submicrometre carbon nanotube transistors” in Nature Electronics.

The content above is a summary. For more details, see the source article.