Key Takeaways

- Schaeffler is developing advanced solid-state batteries with compact pressure-controlled modules for better performance.

- The company showcases a complete electric drive system in a side-by-side off-road vehicle to validate their systems engineering approach.

- Innovations include a magnet-free motor design and comprehensive thermal management solutions, enhancing efficiency and sustainability in electric vehicles.

Innovative Advances in Electric Mobility

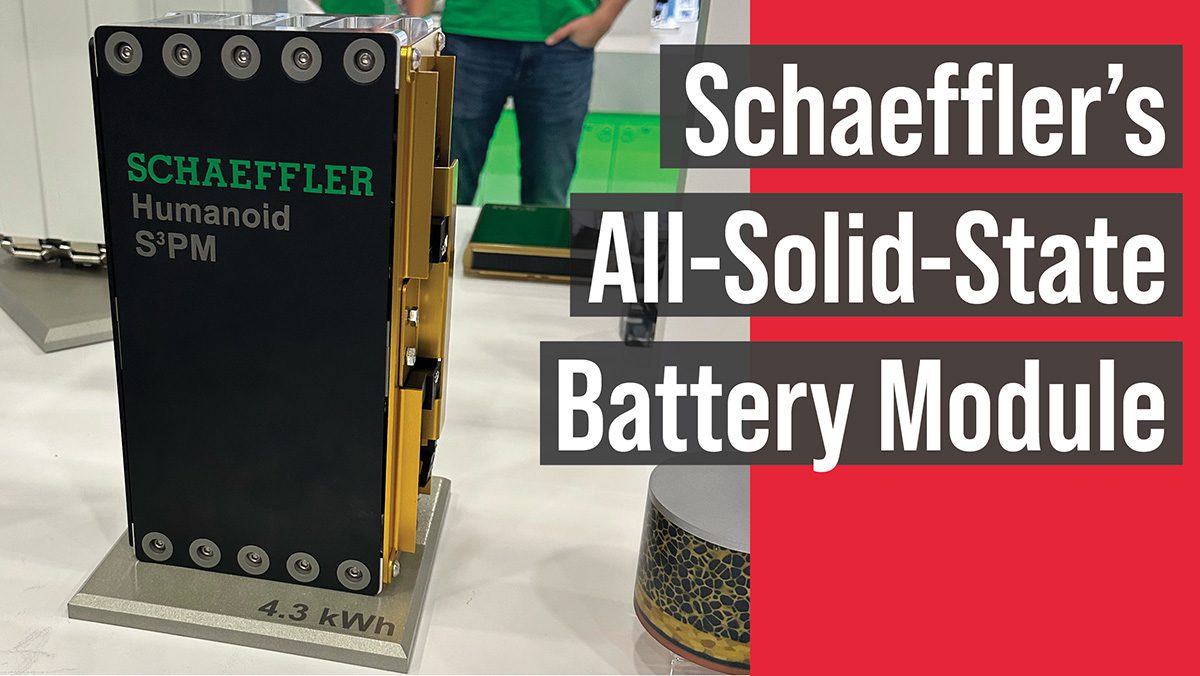

At the Battery Show in Detroit, insights from Schaeffler’s experts revealed their pioneering advancements in electrification and energy storage. Rashid Farahati, Vice President of the Corporate Competence Center for the Americas, detailed the challenges and solutions associated with solid-state batteries, which offer enhanced safety and energy density compared to traditional systems. One major hurdle is that these batteries require sustained mechanical pressure—approximately two megapascals—to function optimally. Schaeffler has developed a compact pressure-controlled module capable of applying up to five megapascals, ensuring more reliable performance for Original Equipment Manufacturers (OEMs).

Farahati also emphasized the benefits of a true all-solid design. By substituting the conventional graphite anode with a thin metallic layer, Schaeffler achieves a significant 40–50% reduction in cell volume. This innovation not only enhances the range but also improves weight efficiency. The elimination of flammable liquid electrolytes contributes to greater safety and allows for higher operating temperatures (up to 100 °C) than today’s liquid systems (around 40 °C). This development simplifies thermal management hardware, promoting potentially quicker charging solutions.

Next, Jerry Dixon, another VP at Schaeffler, highlighted a side-by-side off-road demonstrator featuring an integrated electric drive system consisting of an e-axle, charging electronics, and thermal management. This vehicle serves as a practical demonstration of Schaeffler’s systems engineering approach, emphasizing the importance of real-world validation and compatibility for electric mobility solutions.

Micah Steiner, Technical Project Lead, introduced Schaeffler’s magnet-free electrically excited synchronous motor (EESM). By substituting rare-earth permanent magnets with electromagnetic excitation, this motor diminishes the reliance on scarce materials while maintaining comparable power and torque density. This innovative design not only lowers material costs but also simplifies recycling processes, a pertinent issue in the evolving electric vehicle market.

Mitchell Koupal, Product Manager, discussed the company’s extensive range of thermal management and sensing components that bolster advanced battery systems. These include battery immersion coolers, current and pressure sensors, thermal runaway detection devices, and data management control electronics. Koupal emphasized Schaeffler’s dedication to ensuring lightweight yet robust housing for prismatic cells through enhanced stamping technologies.

These discussions with Farahati, Dixon, Steiner, and Koupal illuminate Schaeffler’s commitment to creating a cohesive ecosystem for the next generation of electric mobility. The innovations in high-pressure solid-state modules, magnet-free motors, and comprehensive thermal systems showcase how Schaeffler is addressing the demands for efficiency, sustainability, and safety in future electric vehicles.

For further information, please visit Schaeffler’s website.

The content above is a summary. For more details, see the source article.