Key Takeaways

- BMW aims for zero-defect high-voltage batteries in its Neue Klasse EVs, utilizing AI-supported quality checks during production.

- The automaker’s new battery assembly strategy includes several global factories, enhancing efficiency and minimizing political risk.

- The upcoming Neue Klasse EVs will feature improved range, power, and charging speeds through advanced inverter technology and an 800-volt architecture.

BMW’s Commitment to Battery Quality

BMW is addressing concerns related to electric vehicle (EV) battery failures by prioritizing a zero-defect policy for its high-voltage batteries in the upcoming Neue Klasse EV lineup. This initiative is particularly aimed at reassuring potential customers about the reliability of electric vehicles, which can be deterred by the costs associated with battery replacements.

The Neue Klasse series, set to launch later this year, will include models such as the iX3 crossover, iX5, iX7, and an all-electric version of the 3 Series sedan. BMW’s commitment to quality ensures that every cylindrical cell received from suppliers undergoes thorough checks before being assembled into cell clusters. This process also employs advanced AI technologies to monitor quality throughout production.

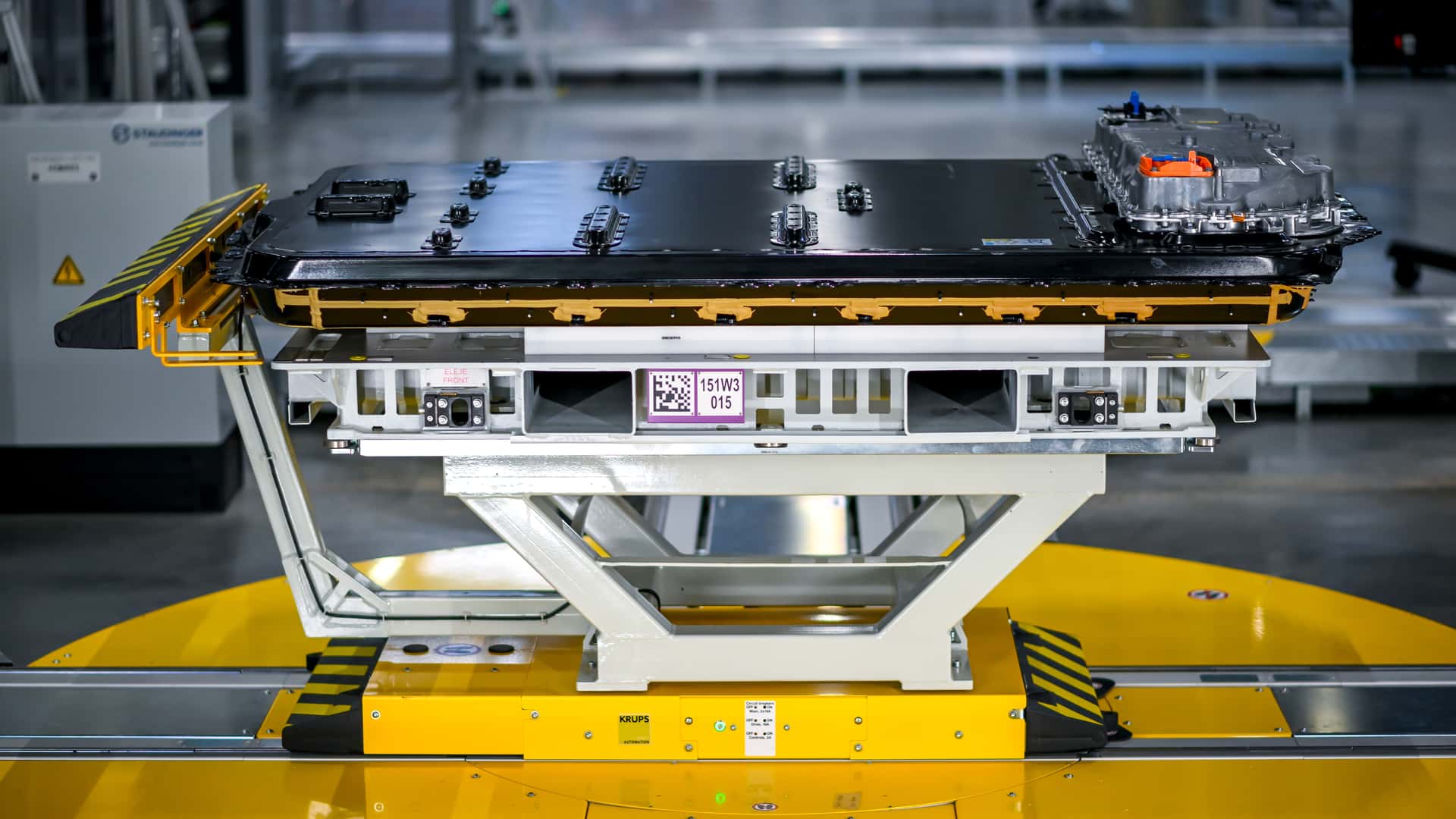

During assembly, cells are linked to coolant systems, laser-cleaned, and welded, followed by a foaming process that secures them as a mechanical unit. Notably, the battery cells are integrated directly into the pack, forgoing individual modules and enabling the pack to serve as a structural component of the vehicle.

Markus Fallböhmer, head of Battery Production at BMW AG, emphasized the importance of this approach: “For production of our high-voltage batteries, we are pursuing a consistent zero-defect approach,” underlining how intelligent, AI-supported quality assurance is central to their strategy.

To support its production goals, BMW has established partnerships with various battery suppliers and has been developing pilot factories since 2023. Once fully operational, BMW will have five battery plants across three continents, including locations in the U.S. and Mexico. This strategy allows the automaker to conveniently assemble battery packs close to vehicle manufacturing sites, reducing logistics complexities and improving efficiency.

The design of BMW’s new EVs will leverage an 800-volt architecture and state-of-the-art inverter technology, promising superior driving range, enhanced power, and faster charging capabilities. By taking these significant steps, BMW is not only setting a higher standard for battery quality but also positioning itself as a competitive player in the evolving electric vehicle market.

The content above is a summary. For more details, see the source article.