Key Takeaways

- Thicker lithium-ion battery electrodes can store more energy but perform poorly due to uneven lithium flow.

- A study from Rice University revealed that internal chemistry, not just structure, significantly affects battery performance.

- The researchers developed a “reaction uniformity number” to help evaluate electrode materials for better efficiency.

New Insights into Battery Performance

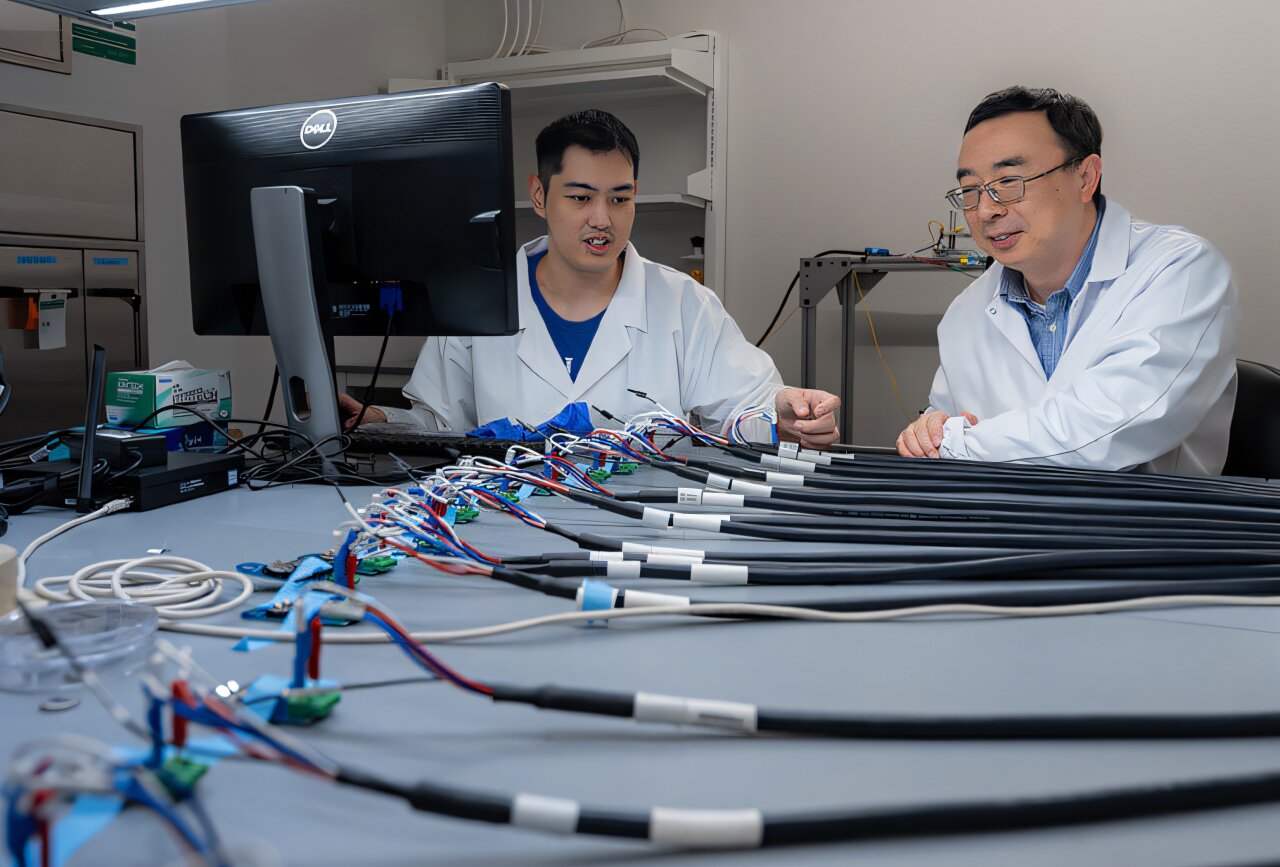

Researchers at Rice University have challenged the prevailing belief in battery technology that the design of pore channels in thick electrodes primarily determines their performance. The team, led by Ming Tang, found that the internal chemistry of battery materials plays a more crucial role in energy flow and overall functionality.

Zeyuan Li, a doctoral alumnus and first author of the study, explains that although thicker battery electrodes can store more energy—beneficial for applications ranging from smartphones to electric vehicles—their ability to charge and discharge rapidly is compromised. He likens this to filling a thick sponge with water unevenly, where only parts of the sponge absorb the liquid.

In their study published in Advanced Materials, the researchers compared lithium iron phosphate (LFP) and nickel manganese cobalt oxide (NMC) as electrode materials. Despite having similar structural characteristics, the NMC electrodes demonstrated superior performance. The LFP materials were found to degrade more quickly under the same cycling conditions due to uneven lithium flow, resulting in internal cracking and loss of capacity.

Using high-resolution X-ray imaging at Brookhaven National Laboratory, the team investigated the movement of lithium ions within each electrode during operation. They discovered that LFP electrodes exhibited intense reaction “hot spots” near the surface, while deeper regions remained inactive. This lack of uniformity persisted even after the battery rested. In contrast, NMC electrodes displayed a much more balanced reaction profile.

Tang, an associate professor in materials science and nanoengineering, emphasized that the thermodynamic properties of materials are critical in dictating how chemical reactions spread, offering new avenues for battery design improvements. The findings led the team to establish a new metric called the “reaction uniformity number,” which takes into account both structural and thermodynamic factors influencing battery performance.

Tang noted that uneven degradation leads to premature wear and wasted storage in batteries. The discovery provides engineers with valuable guidelines for selecting appropriate materials, microstructures, and geometries to enhance the efficiency of thick battery electrodes.

The advancements from this research could have significant implications for the future of battery technology, especially in the development of longer-lasting and more efficient batteries for various applications.

The content above is a summary. For more details, see the source article.