Key Takeaways

- General Motors will introduce lithium-manganese-rich (LMR) batteries in production trucks and SUVs by 2028.

- LMR batteries promise lower costs and higher energy density compared to existing technologies while utilizing more abundant materials.

- The shift to prismatic cells is designed to streamline production, reduce weight, and optimize battery design.

GM’s Transition to LMR Battery Technology

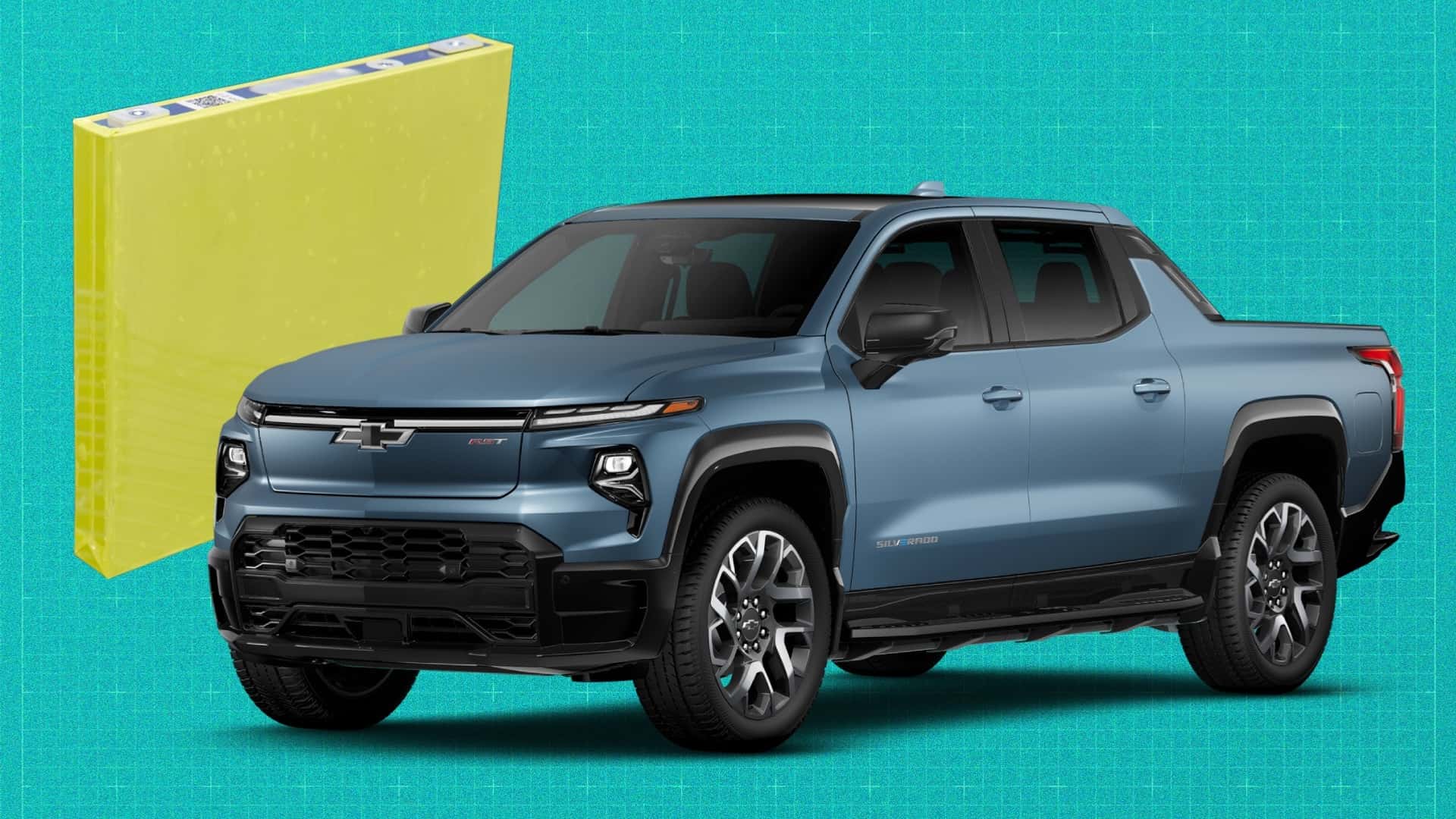

General Motors (GM) announced plans to lead the automotive industry by integrating lithium-manganese-rich (LMR) batteries in their production trucks and full-size SUVs starting in 2028. This initiative represents a significant departure from the current reliance on nickel-manganese-cobalt (NMC) and lithium-iron-phosphate (LFP) batteries, as well as the company’s long-standing use of pouch cells.

GM intends to employ LMR cells in a prismatic format, enhancing their electric vehicle (EV) offerings. Despite this transition, GM will maintain its existing LFP and NMC batteries, providing customers with diverse choices based on their specific needs.

The LMR battery chemistry offers substantial improvements. It is touted to rival LFP in cost while delivering performance metrics closer to those of NMC. By relying on a higher percentage of manganese—an abundant and inexpensive material—instead of the more costly nickel and cobalt, GM aims to decrease overall production costs while increasing energy density.

### Benefits of Prismatic Cell Design

The shift to prismatic cells is expected to yield several advantages. These cells, characterized by a square or rectangular shape, facilitate a modular and space-efficient design, which enhances the integration within battery packs. According to Andy Oury, a battery engineer at GM, the transition from pouch to prismatic cells allows for a significant reduction in the number of parts required—75% fewer parts at the module level and 50% at the pack level. This simplification not only lowers costs but is anticipated to save hundreds of pounds in weight.

GM’s journey toward LMR battery development has been underway for the past decade but accelerated during the COVID-19 pandemic. The company initiated in-house research in 2020, created a demo cathode in 2021, and produced a full batch of LMR cells in 2023. Furthermore, GM recruited battery expert Kurt Kelty from Tesla to lead their battery and propulsion efforts. Initially skeptical about prismatic cell technology, he was convinced by his team of the benefits this design offers in energy density and cost-effectiveness.

### Future Prospects and Challenges

While the prismatic LMR cells show promise, they are still three years away from mass production. The automotive industry is ramping up to meet the evolving demand for electric vehicles, but established players like Tesla have a significant advantage with their mature technology. As GM navigates its production challenges, they are adapting their strategies to innovate and overcome bureaucratic barriers.

Despite the advantages of LMR technology, questions remain about its readiness for the market. The transition may prove too complex for existing models, requiring careful planning and adjustment. However, GM’s willingness to rethink traditional methods and technologies may position them favorably in the competitive EV landscape.

As GM moves forward, the success of LMR batteries will depend on the company’s ability to streamline production processes and deliver innovative solutions that accommodate the unique demands of the American electric vehicle market. This strategic pivot could serve as a blueprint for other automakers aiming to enhance efficiency and sustainability within their own operations.

The content above is a summary. For more details, see the source article.