Key Takeaways

- A novel dual-mode MEMS sensor developed by Chinese researchers enhances vacuum pressure detection with a wider measurement range and improved accuracy.

- The sensor can detect pressures from 0.3 Pa to 100,000 Pa using a compact chip, significantly smaller than traditional sensors.

- It performs reliably across various temperatures and gas types, making it suitable for applications in semiconductor manufacturing and engineering.

Innovative MEMS Sensor Design

A research team led by Profs. Chen Deyong and Wang Junbo at the Aerospace Information Research Institute of the Chinese Academy of Sciences has developed an advanced microsensor designed to improve the accuracy and measurement range of vacuum pressure detection. The study appears in the journal Microsystems & Nanoengineering.

Vacuum sensors are crucial in high-tech industries, particularly in semiconductor manufacturing, where precise pressure control is essential for processes like chemical vapor deposition and plasma etching. Traditional sensor technologies often involve a compromise between measurement range and accuracy. For example, Pirani gauges can measure a wide range but lack precision, while capacitance diaphragm gauges (CDGs) offer high accuracy but have a limited range. Composite sensors that combine both methods tend to be large, complex, and sensitive to gas types.

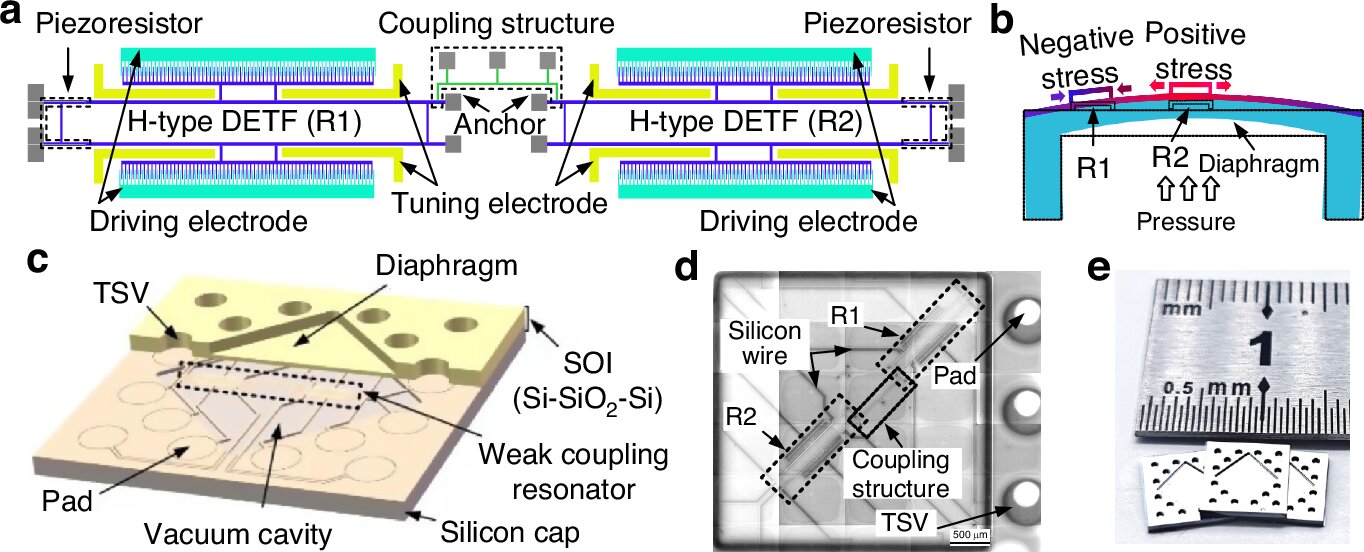

To address these challenges, the research team has developed a micro-electromechanical systems (MEMS) sensor that operates efficiently over six orders of magnitude, ranging from 0.3 Pa to 100,000 Pa, using a single sensing element. This is accomplished by integrating two operating modes into a single chip. At lower pressures (0.3 Pa–1,000 Pa), the sensor uses a mode-localization feature, amplifying tiny pressure changes into detectable signals. When operating at higher pressures (1,000 Pa–100,000 Pa), it automatically transitions to a traditional resonance mode characterized by high accuracy and stability.

The dual-mode configuration leads to noteworthy performance improvements, achieving a resolution of about 0.1 Pa in low-pressure conditions and 2.0 Pa in high-pressure scenarios. The sensor exhibits minimal calibration errors, with a relative deviation of only 1.99% at 120°C in low-pressure environments and as low as 0.01% of full scale under high pressure. Additionally, the device operates reliably within a temperature range of –20°C to 120°C and maintains functionality regardless of varying gas types.

Remarkably, all of these advanced features have been integrated into a compact MEMS chip measuring just 27.2 mm³. This size is impressive when compared to conventional commercial sensors, which can be over 200 times larger.

The research presents significant implications for various industries, particularly in semiconductor fabrication, space exploration, and high-precision engineering, where reliable vacuum pressure measurements are critical.

For further details, please refer to the published study: Jiaxin Qin et al, “A novel high-performance wide-range vacuum sensor based on a weak-coupling resonator,” Microsystems & Nanoengineering (2025).

The content above is a summary. For more details, see the source article.