Key Takeaways

- Rimac Technology unveiled advanced EV battery platforms and powertrains aimed at large-scale production.

- The new battery system features solid-state technology and is designed for improved energy density and safety.

- Rimac’s electronics portfolio focuses on consolidating traditional control units into high-performance ECUs, facilitating advanced vehicle operations.

Innovative Developments at IAA Mobility

Rimac Technology showcased cutting-edge electric vehicle (EV) solutions at the IAA Mobility, introducing new battery platforms, compact powertrains, and advanced electronics. These innovations, developed in collaboration with ProLogium, Mitsubishi Chemical Group, and Kautex Textron, are tailored for mass production and poised for deployment in a significant number of vehicles in the near future.

The crux of Rimac’s new offerings is its next-generation battery system. This system features solid-state cell technology, developed in conjunction with ProLogium and Mitsubishi Chemical Group. By integrating these solid-state cells with advanced materials from Mitsubishi, Rimac claims to have achieved a system that is not only lighter but also offers greater energy density and enhanced safety compared to earlier battery generations. For immediate EV applications, the “Evo Technology” battery utilizes 46XX Gen2 nickel manganese cobalt (NMC) cells within a thermoplastic composite housing, co-designed with Kautex Textron. This setup is engineered for optimized thermal management, addressing critical factors for EV performance.

Further enhancing versatility, Rimac’s battery platform supports both high-energy and high-power configurations utilizing either 46XX or 2170 cell formats. This scalable architecture incorporates a cell-to-pack design with integrated safety features, ensuring robust performance across various applications.

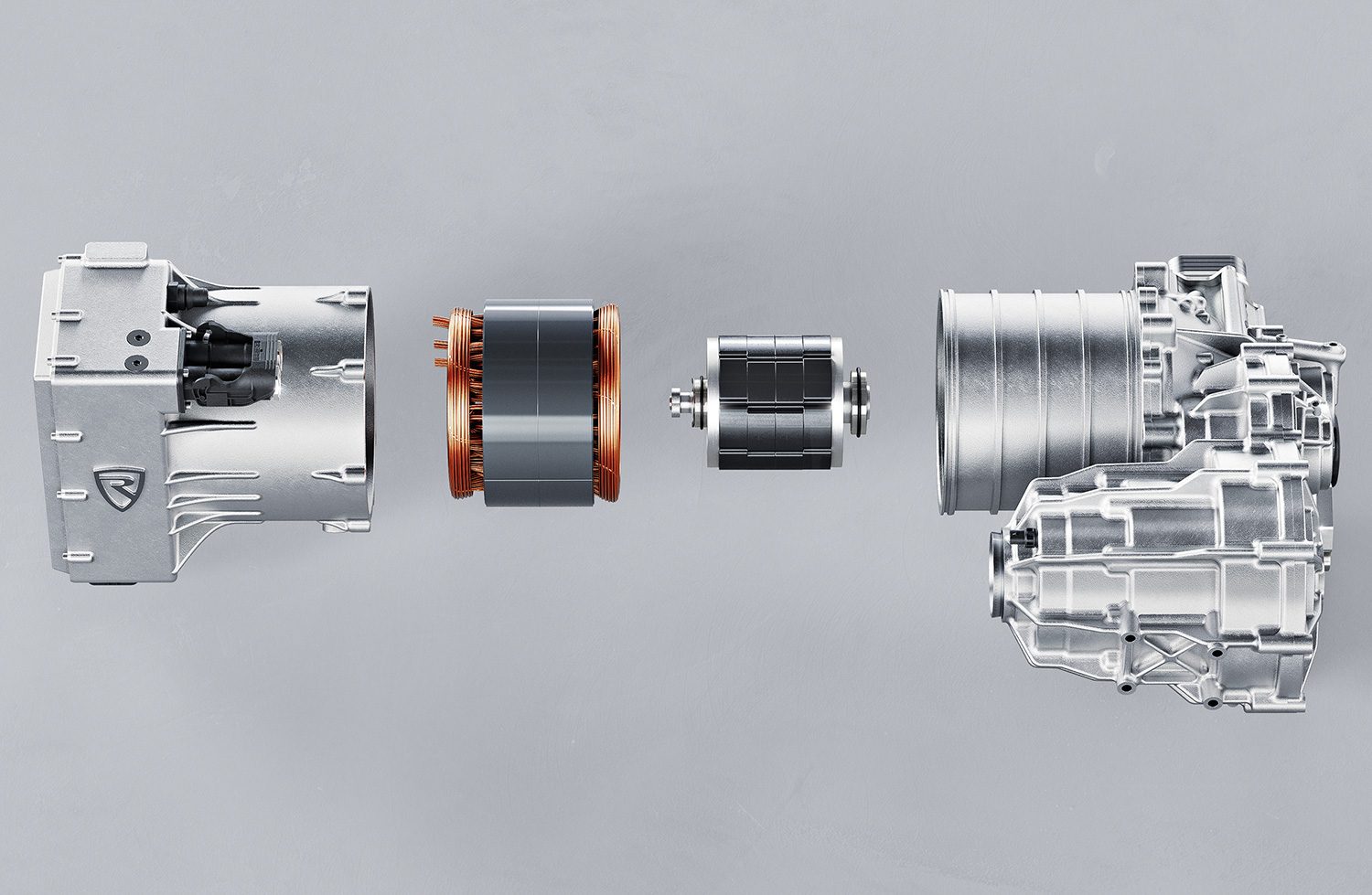

In the realm of powertrains, Rimac introduced the SINTEG 300 and 550 single electric motor eAxles. These units boast remarkable power density of over 8 kW/kg and torque density exceeding 90 Nm/kg. The innovative rotor design allows speed capabilities of up to 25,000 rpm, with options for coaxial and offset layouts offering outputs between 150 to 360 kW and torque ranging from 2,500 to 6,250 Nm. These products target a wide spectrum of EV applications, from high-performance sports coupes to larger SUVs. Additionally, Rimac is gearing up to manufacture its high-torque “XXL Axle,” a dual-motor configuration validated at over 11,000 Nm, expected to enter production in 2026 with a major global automaker, achieving peak efficiencies exceeding 95 percent.

Rimac is also innovating in the electronic control landscape, unveiling a suite of domain and zonal electronic control units (ECUs) utilizing NXP’s S32E2 processors. These advanced units aim to consolidate multiple traditional ECUs into high-performance controllers. They are responsible for managing critical vehicle tasks, including torque vectoring, battery management, and high-voltage distribution. The design adheres to centralized software-defined vehicle principles, enabling real-time operations, over-the-air updates, and compliance with advanced safety standards.

The newly launched technologies will be produced at Rimac’s Croatian facilities, which cover over 95,000 square meters across two sites, including their main campus. Nurdin Pitarević, COO of Rimac Technology, emphasized the significance of the showcased innovations, stating that these are not merely conceptual technologies but production-ready solutions poised to influence the future of EV manufacturing on a large scale.

The content above is a summary. For more details, see the source article.