Key Takeaways

- Rivian focuses on improving EV battery charging speed without compromising energy density.

- Chinese firms lead in fast-charging technology, but achieving balance with battery longevity remains a challenge.

- Existing battery technologies, like high-nickel cells and lithium-iron phosphate (LFP), are expected to dominate the market amid solid-state battery skepticism.

Advancements in EV Battery Technology

Electric vehicle (EV) batteries have become significantly more efficient and affordable over the past decade as the demand for sustainable transportation increases. However, Rivian CEO RJ Scaringe believes there is still substantial potential for innovation, particularly in developing faster charging capabilities without sacrificing energy capacity.

In a recent interview on the Plugged-In Podcast, Scaringe discussed Rivian’s commitment to enhancing battery technology to reduce charging times. Current public charging processes for most U.S. EVs typically take 20 to 40 minutes for a meaningful charge due to the trade-off between charging speed and energy density. Scaringe emphasized the need for a balance, stating, “We try to find the right balance on those.”

The pursuit of faster charging presents its own set of complications, particularly concerning battery longevity. According to Scaringe, although rapid charging is technically feasible, it may significantly degrade battery durability—an outcome that could reduce the cell’s capacity by 20 to 25% over about 1,000 charge cycles.

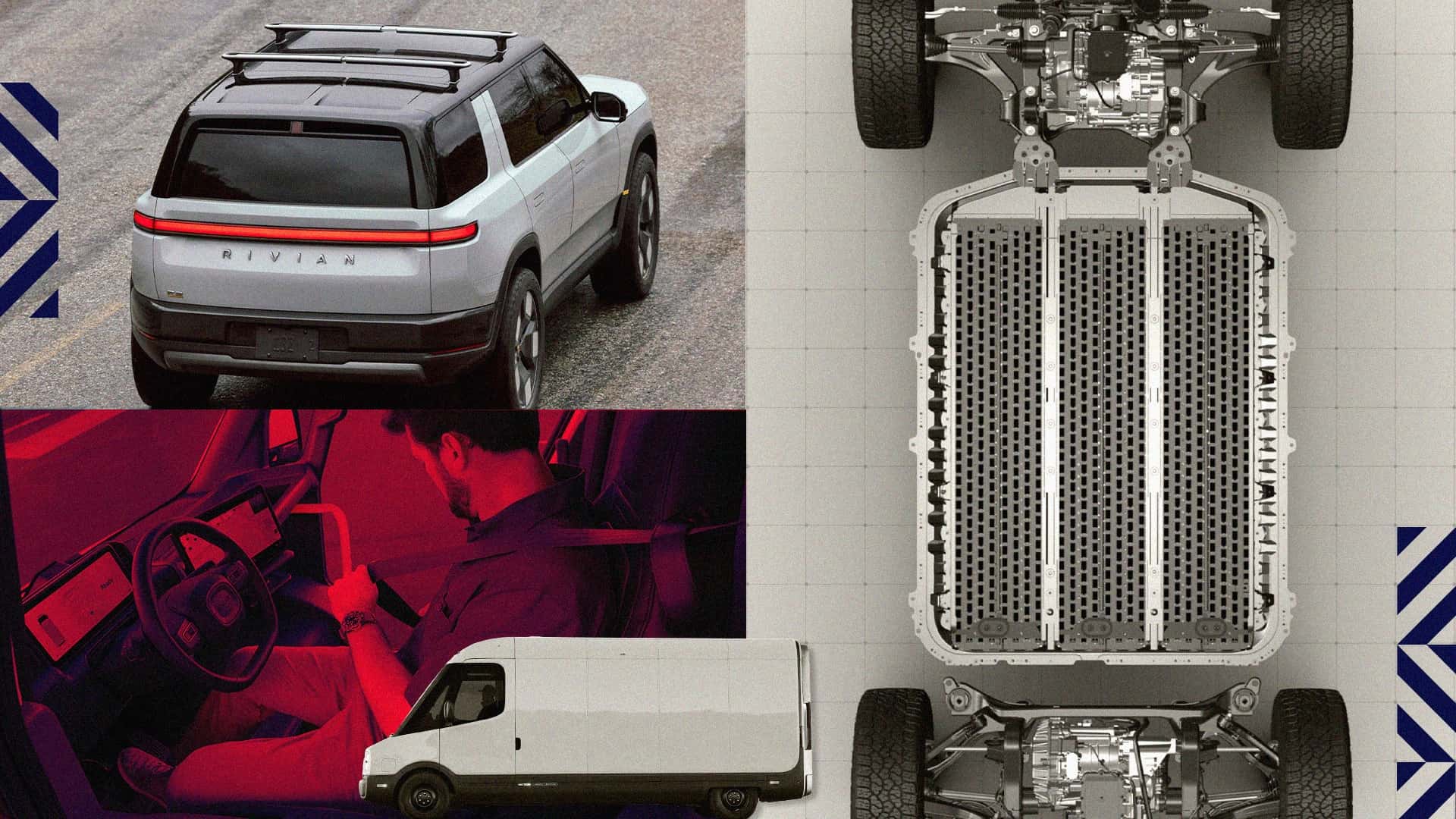

Rivian is exploring various chemistry modifications, including the use of silicon anodes, to address charging speed without compromising energy density. The company is also implementing structural design innovations, such as larger battery cells for its upcoming R2 crossover, which are constructed in a single layer instead of stacked. These advancements not only enhance performance but also aim to reduce overhead costs associated with battery manufacturing, which is typically the most expensive component of EVs.

When questioned about emerging battery technologies, such as solid-state batteries, Scaringe expressed skepticism about their readiness for commercial application. Despite significant investment and development efforts in solid-state technology, no company has yet achieved widespread production. He underscored the importance of producing new battery chemistries reliably at scale, stating that while there are several promising alternatives being explored, their viability remains unproven.

Currently, Rivian employs two of the most widely used battery types in the EV market: high-nickel cells and lithium-iron phosphate (LFP) batteries. While LFPs are appreciated for their durability and cost-effectiveness, Scaringe pointed out that trade barriers could hinder their adoption in the U.S. market. China dominates the global supply of LFPs, limiting their availability in the U.S. unless trade policies change.

As Rivian continues to innovate and improve battery technology, the company aims to provide a more convenient and efficient experience for EV owners. Faster charging without compromising battery life is a critical goal that could revolutionize the adoption of electric vehicles for long-distance travel and for those without home charging options. The ongoing developments in battery technology will play a pivotal role in shaping the future of sustainable transportation.

The content above is a summary. For more details, see the source article.