Key Takeaways

- ZF’s TempAI technology enhances electric motor temperature management, improving performance by over 15%.

- The AI-driven platform reduces energy consumption during dynamic driving scenarios by 6% to 18%.

- TempAI significantly cuts development time, transforming months-long processes into mere days.

Innovative Temperature Management for Electric Motors

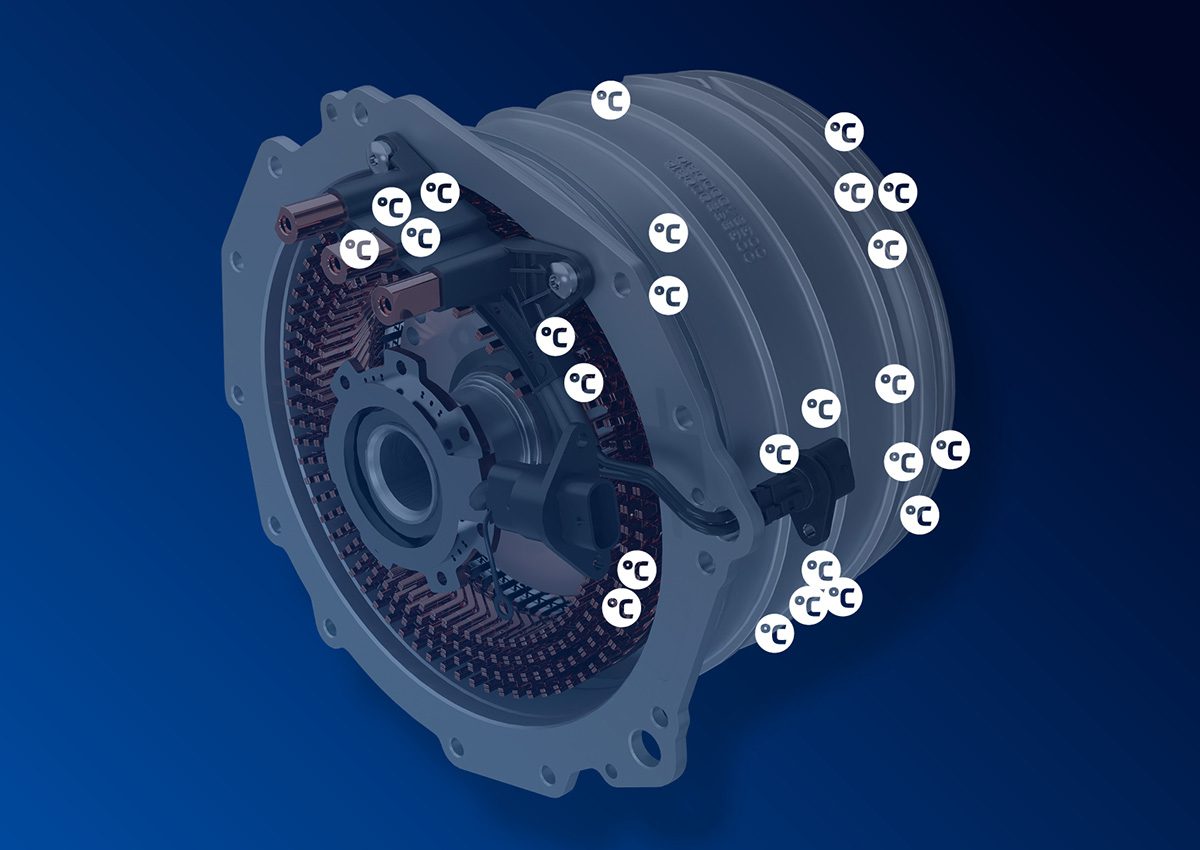

ZF has launched TempAI, a cutting-edge AI-based temperature management solution aimed at enhancing the performance and efficiency of electric motors in electric vehicles (EVs). This innovative technology utilizes a self-learning temperature model, which has been shown to improve temperature prediction accuracy by over 15%. As a result, electric motors can achieve more precise thermal usage, increasing performance without sacrificing reliability.

The TempAI platform is designed for rapid deployment and minimal resource requirements. It automatically generates physics-based models from extensive measurement data, allowing for quick integration with existing control units. This cost-effective implementation can seamlessly transition into series production. ZF claims that TempAI provides targeted electric motor control that operates right up to thermal limits, which leads to a peak power increase of up to six percent. Furthermore, measurable efficiency gains have been recorded during the Worldwide Harmonized Light Vehicle Test Procedure (WLTP) cycle. In dynamic driving scenarios, such as on high-performance tracks like the Nürburgring Nordschleife, the technology can reduce energy consumption by between 6% and 18%, depending on load conditions.

Beyond performance improvements, TempAI also offers ecological advantages by optimizing thermal design and reducing the reliance on heavy rare earth materials commonly used in electric motors. Additionally, the technology minimizes development timelines significantly; processes that typically take several months can be condensed to just days, thanks to AI-driven modeling.

During the motor development phase, TempAI’s AI models learn and effectively forecast internal thermal processes that are often challenging or costly to measure directly, such as rotor temperatures. This leveraging of extensive data—from functional tests on test benches and in test vehicles—allows the technology to analyze millions of data points related to various variables, including ambient temperatures, rotor speeds, and driving behavior patterns.

Dr. Stefan Sicklinger, who oversees AI, Digital Engineering, and Validation in ZF’s R&D department, commented on the transformative potential of this technology, stating, “This technology enables us to further increase the efficiency and reliability of our drives. At the same time, TempAI demonstrates how data-driven development can be not only faster, but also more sustainable and more powerful.”

ZF’s introduction of TempAI marks a significant step forward in the realm of electric vehicle technology, promising enhancements in both performance and sustainability.

The content above is a summary. For more details, see the source article.